Introduction

Introduction

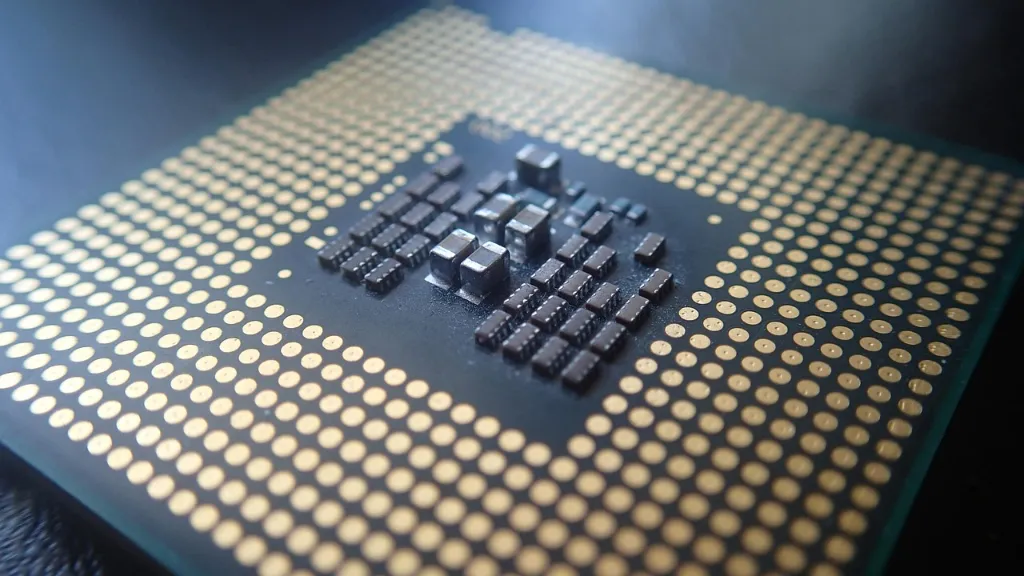

Defect detection keeps electronics manufacturing running smoothly. Without it, faulty products slip through, costing time and money. Tiny parts like chips and circuits pose big challenges. Reflective metals glare under lights, and textures vary wildly. Picking the right lens sharpens images, boosts accuracy, and lifts yields. That’s the basics.

The Role of Lenses in Electronics Defect Detection

Lenses make or break image quality in inspections. They pull in light and focus details so defects pop out. Magnification zooms in on small flaws. Aperture controls light intake, which matters for contrast. Working distance lets you set up without bumping equipment. Get these wrong, and the whole system suffers.

High optical quality means sharper edges and less blur. In automated setups, that translates to faster scans and fewer errors. Machines rely on clear data to spot issues. Poor lenses lead to missed defects or false positives. It’s all about reliability in high-volume lines.

Sometimes, folks overlook how lenses interact with cameras. Sensor size plays a part too. Match them poorly, and you get cropped views or distortion. But nail it, and inspections hum along.

Lens Types Commonly Used in Electronics Inspection

High Resolution Lenses for Micro Defect Detection

High resolution Lens capture tiny details on PCBs and solder joints. Cracks show up crisp. Solder bridges, those unwanted connections, become obvious. Even dust particles that could short circuits get flagged.

They’re built for precision. Pixels pack in tight, revealing flaws under a micron. In assembly lines, they catch problems early. Saves rework down the line. (e.g. AICO’s 2/3″ 8mm 20mp m12 mount compact machine vision FA board lens )

Macro Lenses for Close Range Inspection

Macro lens shine at short distances. Focus stays sharp up close. Connector pins look huge and clear. Chip surfaces reveal scratches or pits. Bonded areas, like wire attachments, get inspected without strain.

They’re handy in tight spaces. No need to move parts far. Just position and shoot. Makes workflows quicker.

Low Distortion Lenses for Dimensional Stability

Distortion warps images, messing up measurements. Low distortion lenses keep shapes true across the frame. Edges don’t bend. Centers stay accurate.

In automated systems, this matters for positioning robots or gauging sizes. No guesswork. Results hold up every time.

One thing: calibration checks help maintain that stability. But yeah, these lenses do the heavy lifting.

Wide Angle Lenses for Large-Area Scanning

Wide angle M12 machine vision lens grab big views. Whole circuit boards fit in one shot. Display panels too, like in phones or TVs.

They’re great for quick scans. Spot gross defects first, then zoom in. Speeds up initial checks. But watch for edge falloff in quality. Not perfect for everything.

Specialty Lenses for Complex Lighting Conditions

IR lenses handle heat or dark spots. They see thermal patterns on boards. Useful for overheating issues.

Polarized lenses cut glare from metals and glass. Reflections vanish, details emerge. No more washed-out images.

UV lenses pick up coatings or adhesives. Contaminants glow under UV. Spots invisible flaws like residue.

These aren’t everyday picks, but in tough environments, they save the day. Like inspecting in dim factories or under bright LEDs.

How to Choose the Right Lens for Your Inspection Setup

Start with field of view. Match it to sensor size. Too small, and you miss edges. Too big, details fade.

Working distance depends on setup. Conveyor belts need room. Robotic arms might allow closer.

An AICO high-resolution lens optimized for SMT line inspection improved detection consistency and reduced false alarms.

Test a few options. See what fits the line speed and part types. Budget counts, but cheap lenses often cost more in downtime.

Ever notice how some setups evolve? What works for prototypes might flop in production. Adapt as needed.

Optimizing Image Quality in Industrial Inspection

Balancing Lens Aperture and Lighting

Aperture size tweaks light flow. Wide open, more light but less depth. Stopped down, sharper but dimmer.

Pair with lights for balance. LEDs work well. Adjust intensity to avoid shadows or hotspots.

Contrast boosts defect visibility. Overexpose, and details wash out. Underexpose, and noise creeps in. Trial and error helps.

Ensuring Mechanical Stability

Vibrations shake focus. Heat warps parts. Lenses need tough builds.

AICO’s precision-engineered housings maintain consistent focus under high-speed conditions. They resist shakes and temps.

Mounts matter too. Secure them tight. In busy factories, this prevents drifts.

One quirk: dust buildup over time. Wipe gently, or it scratches.

Regular Calibration and Maintenance

Clean lenses often. Use soft cloths, no harsh stuff. Fingerprints smear images.

Align optics periodically. Tools measure shifts. Catch drifts early.

In long runs, check for wear. Seals fail, moisture sneaks in. Simple habits extend life.

Emerging Trends in Electronics Imaging

AI systems crave top-notch images. They analyze patterns fast, but garbage in means garbage out. Lenses must deliver fidelity.

Compact industrial lenses fit tight spots. Drones or portables use them. Lightweight too, for moving setups.

Coatings advance. They repel dust, cut reflections. Handle harsh environments better.

Think about sustainability. Some makers push eco-friendly materials. Not core yet, but gaining traction.

Integration with software grows. Lenses talk to apps for auto-adjusts. Smarter inspections ahead.

Conclusion

The right lens nails defect detection in electronics. It ramps up accuracy and efficiency. Yields climb, costs drop.

Optical investments pay off in reliability. Systems run smoother.

AICO, as a trusted industrial lens manufacturer, continues to support advanced inspection applications with tailored optical solutions.

FAQ

Q: What makes high-resolution lenses ideal for micro defects?

A: They zoom in on tiny flaws like cracks or dust without losing detail. Perfect for PCBs where precision counts.

Q: How do polarized lenses help with reflective surfaces?

A: They filter out glare from metals or glass, making hidden defects visible. Cuts down on lighting headaches.

Q: Is working distance important in lens selection?

A: Yes, it affects setup flexibility. Short distances suit close work, longer ones fit conveyor systems.

Q: Why calibrate lenses regularly?

A: To keep focus sharp and avoid drifts from vibrations or heat. Prevents errors in inspections.

Q: Can wide-angle lenses handle detailed work?

A: They’re better for overviews. For fine details, switch to macro or high-res types.

Q: What’s the deal with UV lenses in electronics?

A: They detect invisible stuff like adhesives or contaminants that show under UV light. Niche but useful.