Role of Chief Ray Angle in Wide Angle Lens Design

Optical Principles Behind Chief Ray Angle

Chief Ray Angle (CRA) refers to the angle at which the principal ray—often representing the central light ray from a scene point—strikes the image sensor after passing through the lens.

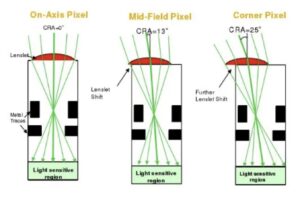

This angle plays a pivotal role in wide angle lens design, primarily because wide angle optics inherently cause light rays to enter the sensor at steeper angles, especially toward the edges. In wide angle lenses, the optical geometry is such that the CRA increases significantly at the periphery of the field.

Wide angle lenses often produce higher CRA values due to their optical geometry. This affects how uniformly light hits the sensor across the image plane, influencing exposure and color accuracy.

Relationship Between CRA and Sensor Compatibility

Not all image sensors are designed to handle high CRA values. Most CMOS sensors have angular sensitivity characteristics that must align with the CRA of the lens for optimal performance.

A mismatch between the lens’s CRA and sensor’s angular acceptance can lead to vignetting, color shading, or even loss of detail near the frame edges. CMOS sensors with low CRA tolerance require careful lens selection.

Manufacturers like AICO address this issue by engineering M12 macro lenses compatible with a wide range of sensor formats. Their 12mm 10MP M12 macro lens is optimized for 2/3″ sensors and designed to maintain sharpness and minimize distortion even under varying CRA conditions.

Impact of Chief Ray Angle on Image Quality Metrics

Influence on Relative Illumination

As CRA increases, especially in wide angle designs, relative illumination tends to drop off at the corners. This is due to the oblique angle at which light enters the sensor, leading to decreased brightness and uneven exposure across the frame.

Higher CRA can cause light fall off at image corners, reducing uniformity. To counteract this, manufacturers often integrate corrective optics or design sensors with microlens arrays angled to better capture light entering at steep angles.

Corrective optical elements or sensor microlens adjustments may be needed. For instance, AICO’s ACN127B198M12MM board lens delivers 55% relative illumination at a maximum CRA of 11.5°, providing a strong balance between wide field of view and brightness uniformity.

Effect on Modulation Transfer Function (MTF) Performance

MTF measures a lens’s ability to resolve fine detail. When CRA exceeds the sensor’s angular acceptance limit, MTF performance degrades sharply—especially at the periphery—resulting in reduced contrast and sharpness.

MTF degradation occurs when CRA exceeds sensor acceptance angles. Designers must carefully balance CRA to ensure edge resolution remains high without compromising center performance.

Lenses like AICO’s 16mm F2.8 M12 machine vision macro lens are engineered for this balance, with distortion kept under 0.1% and optimized for consistent detail across the entire field of view.

Design Considerations for Wide Angle Lenses with High CRA Requirements

Managing Total Track Length and Lens Diameter Constraints

A high CRA typically requires a short back focal length, which places constraints on mechanical design and optical element layout. High CRA designs often require shorter back focal lengths. Compact systems like M12 lenses must juggle limited space with optical performance goals.

Mechanical tolerances also become critical; even slight misalignments can shift the CRA enough to cause imaging defects.

Techniques to Optimize Lens Sensor Alignment

To meet high CRA demands, advanced techniques such as tilted image planes or offset microlens arrays are used. Tilted image planes or offset microlenses help adapt to high CRA designs. These approaches help align incoming rays more effectively with pixel sensitive areas.

Application Specific Demands for Controlled Chief Ray Angle

Surveillance and Security Imaging Systems

In surveillance applications, edge to edge clarity is crucial. High CRAs can degrade edge quality unless properly managed. Peripheral image clarity is critical in wide area monitoring solutions.

Controlled CRA ensures footage remains sharp even under variable lighting conditions—key for face recognition or license plate reading.

Machine Vision and Industrial Automation Cameras

Machine vision requires precise illumination across sensors to detect fine patterns or defects. Controlled CRA distribution prevents inconsistencies that could lead to misreads or false positives.

Accurate edge detection relies on consistent illumination across sensors. AICO’s 25mm F8 M12 macro lens is ideal for such use cases, offering manual focus control and high resolution for automated inspection systems.

The adaptability in manual focus control makes the 25mm lens an ideal partner to give businesses further tuning of the system to bring up that clarity and sharpness to your applications.

Advances in Optical Engineering Addressing Chief Ray Angle Challenges

Innovations in Sensor Architecture Supporting Higher CRAs

Recent advancements in sensor architecture include refined microlens arrays that accept steeper ray angles without sacrificing efficiency. Modern sensors incorporate advanced microlens arrays to accept steeper angles. This allows lens designers greater freedom to create compact systems while maintaining high image quality.

These innovations open doors for ultra wide angle lenses like fisheye types without excessive compromise in corner performance.

Future Trends in Wide Angle Lens Development

Looking ahead, hybrid glass resin materials are being integrated into lens groups to improve angular light response without adding complexity. Simulation driven workflows are becoming standard in optical design, allowing more accurate prediction of CRA behavior under various sensor alignments.

Simulation driven design workflows enhance accuracy of CRA predictions. AICO continues pushing boundaries with adaptive optics technologies aimed at next gen platforms where CRA control will be even more critical.

FAQs

Q: What happens if CRA is too high for a given sensor?

It can cause vignetting, color shading, and reduced sharpness at image corners.

Q: Why is chief ray angle especially important in wide angle lenses?

Wide angle optics naturally increase ray angles toward edges, making CRA control vital.

Q: Can software correct issues caused by CRA mismatch?

Some correction is possible, but hardware optimization (lens and sensor) yields better results.

Q: How does AICO address CRA challenges?

Through precision alignment techniques and custom optics tailored for different sensor formats.

Q: Are all sensors equally tolerant to high CRA values?

No; some CMOS sensors have lower angular tolerance requiring compatible lens designs.