With the advent of 2025, industrial imaging is undergoing a sea change with the increased application of machine vision technology. It is no longer a sidelines application now, as machine vision has become a central element in bringing efficiency, accuracy, and security to industries.

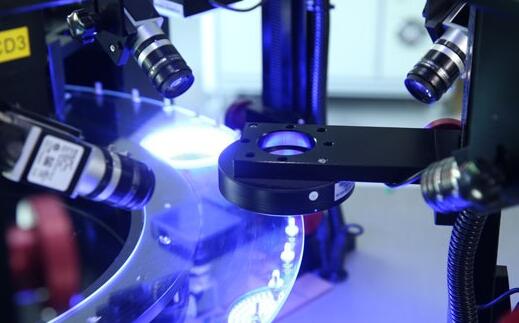

At the core of every machine vision system lies a critical element: the lens, which captures and focuses light to create high-quality images to inspect. Yet who are the corporate titans behind the machine vision lens revolution, and how are they spearheading this industrial imaging revolution?

Why Is Industrial Imaging Advancing So Rapidly?

The Growing Demand for Automation

The high growth in industrial imaging is a result of the growing need for automation in industries today. Companies are increasingly leveraging machine vision systems to:

Automate inspection and defect detection in production lines.

Enhance efficiency in operations by minimizing human error and workflow automation.

Ensure consistent product quality without additional production expenses.

As industries have demanded more productivity and accuracy, the application of machine vision systems has grown by leaps and bounds.

The Role of Emerging Technologies

Emerging technologies are also accelerating the development of industrial imaging. These key developments are:

Artificial Intelligence (AI) and Machine Learning (ML): AI-enabled image processing delivers real-time defect detection and predictive maintenance.

5G and Greater Connectivity: Fast data transfer speeds enhance the performance of machine vision in real-time applications.

High-Resolution Sensors: Ultra-high-definition imaging has rendered better quality lenses and sensors a requirement.

With industries such as automotive, aerospace, healthcare, and consumer electronics requiring more accuracy and sustainability, machine vision has been an integral part of industrial processes in the modern world.

Why is the Lens Such a Key Component in Machine Vision Systems?

The Lens as the “Eye” of Machine Vision

In a machine vision system, the lens is the eye that collects and concentrates light onto the camera sensor. The quality of the lens directly impacts image quality, resolution, and system performance. Several important factors determine the performance of a machine vision lens:

Optical Specifications That Matter

Focal Length: Determines the magnification and working distance of the imaging system.

Aperture (F/No): Regulates the flow of light and depth of field.

Field of View (FOV): Determines the imaged region of the lens.

Optical Distortion: Must be kept low for true image representation.

Low distortion, high resolution, and correct FOV are demanded by a quality lens to provide consistent and precise imaging outputs in industrial application.

Who are the Leading Machine Vision Lens Companies in 2025?

Hangzhou Ai Ke Electronics Co., Ltd. (AICO): Foremost Optical Innovations

AICO is among the foremost manufacturers in the market for machine vision lenses. AICO has made a name for itself as a provider of quality optical products with uses particularly for industrial image.

Accolades for Research & Development

AICO follows a culture of precision and innovation in lens manufacturing. Their R&D focus is placed on:

Manufacturing high-resolution lenses that are applicable to stringent imaging requirements.

Higher image format compatibility, ranging from 1/2” to film size.

Enhanced optical coatings for better light transmission and more defined images.

Improved Manufacturing & Quality Control

AICO maintains cutting-edge manufacturing facilities with:

State-of-the-art coating equipment for broadband Anti-Reflection (AR) coating.··

1K class clean room assembly lines providing consistency, economy, and efficiency.·

Authentications such as ISO 9001, CE, RoHS, and FCC, testifying to their commitment to quality.

Their OEM & ODM service provision also makes AICO a responsive and customer-centric manufacturer.

Variety Lens Offerings

AICO provides a wide range of machine vision lenses, including:

C-Mount and CS-Mount lens for use with various industrial cameras.

2.8mm 10mp 4K C / CS mount ultra wide angle industrial vision lens with 160 degree FOV and minimal distortion for use in wide-angle applications.

1.1″ 20mp c mount industrial vision lens for capturing ultra-high definition images.

Their commitment to offering affordable yet high-performance lenses has made AICO a reputable brand.

What Are the Most Significant Trends Shaping Machine Vision Lens Technology in 2025?

Higher Resolution for High-Resolution Inspection

As sensor technology continues to advance, 4K and 8K resolution lenses are increasingly becoming a standard in machine vision. This allows for:

Increased defect detection in manufacturing.

Enhanced pattern recognition and AI-driven analysis.

Increased accuracy in metrology and measurement applications.

Low-Distortion Lenses for Precision Applications

High-accuracy measurement applications such as metrology and semiconductor manufacturing require low-distortion optics. Manufacturers are attempting to reduce distortion to near zero.

Wide-Angle Lenses for Wider Fields of View

ultra wide angle industrial vision lenses are being increasingly used in applications such as logistics and warehouse automation. They:

Reduce the number of cameras necessary.

Optimize the performance of tracking and monitoring systems.

Decrease the need for multiple viewing.

Provide complete coverage for robot vision systems.

Compact & Rugged Lens Designs

With machine vision systems being utilized more in harsh environments, there is a need for compact and rugged lenses that can withstand:

High humidity and temperature.

Industrial-strength shock and vibration.

Chemical and dust exposure.

Compact industrial FA board lens M12 mount

Specialty Optical Coatings for Improved Performance

State-of-the-art anti-reflective coatings are what manufacturers of lenses are investing more in to:

Reduce glare and enhance contrast.·

Reduce ghosting and chromatic aberration.·

Let more light pass through for better imagery in low light.

AI-Based Lens Design

As deep learning-based image analysis is advancing, lenses are now being developed to be completely compatible with deep learning algorithms. This enables:

Real-time defect detection.

Automatic object recognition and classification.

Predictive maintenance and smart manufacturing.

How Are These Innovations Affecting Industrial Applications?

Better Quality Control & Inspection

With better optics and higher resolution, industries can now:

Detect smaller defects more precisely.

Detect defective products earlier in the process, thus minimizing waste.

Enhance overall manufacturing efficiency.

Advanced Vision-Guided Robotics

Machine vision lenses are essential in guiding robots for use in applications such as:

Pick-and-place in assembly lines.

Automated welding and manufacturing.

Precise surgery in medical robotics.

Smarter Warehouse & Logistics Management

High-resolution, wide-angle lenses help in:

Automated inventory tracking.

Package sorting and identification improvement.

Security surveillance in warehouses.

What Does the Future Hold for Machine Vision Lenses?

We can expect even more innovation in optical design, materials, and manufacturing in the future. The future of machine vision lenses will be shaped by:

Growing need for custom optical solutions.

Application of AI-based image systems.

Development of extremely light yet robust lens materials.

Conclusion

The industrial imaging technology trend in 2025 is being spearheaded by the machine vision lens market. Trailblazers like Hangzhou Ai Ke Electronics Co., Ltd. (AICO) are at the forefront, guiding the way to the future with their innovative, high-quality lens technology.

In the wake of industrial automation, precision optics will forever be an integral component, with the “eyes” for the intelligent smart factory and intelligent industrial systems of the future.